Process Planning and Design

Process Planning and Design refers to the complete delineation and description of the specific stages in the production process and the linkages between the stages that enable the production system to produce products or services. These products or services should meet the desired quality standards. They should also be produced at the right time (when the customer wants them) and the total costs associated with their production should be within the budgeted limits.

Process planning is required mostly for new products or services. Replanning is also necessary when business or market conditions change, or technologically superior equipment becomes available, or when the production capacity has to be changed.

The choice of process design is driven by the operations strategy adopted by the organization. The production processes should be planned and designed to produce the ideal mix of products, which is determined by the production plan (which, in turn, reflects the operations strategy of the organization).

For instance, if the strategy of an organization for a particular product line is to produce small batches of products, so that the quantity produced can be easily adapted to the size of the order, the processes should be so designed that they can shift quickly to the production of different products. This makes the production of small batches of the products economically feasible.

In addition to the operations strategy, the product design of the organization also influences its process design. Process design and product (or service) design should be compatible with each other. Process design is said to be effective for an organization only when it is able to accommodate the product/service design. Operations managers often modify the process design on the basis of their experience in designing products and services, or vice versa.

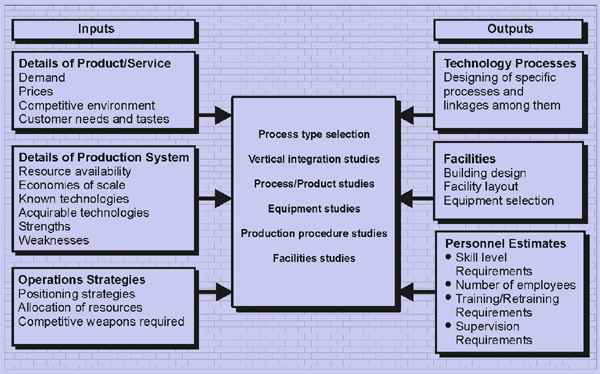

For effective process planning and design, thorough knowledge of operations strategies, product/service designs, technologies of the production system, and market conditions is required. These elements should be set out in a detailed plan for manufacturing the products/services. Figure schematically illustrates the various inputs and outputs of process planning.

Process planning forms the basis for designing factory buildings and facility layouts, and selecting production equipment. It also has a bearing on quality control, job design and capacity in different facilities of the organization. Hence, it is important for operations managers to determine how products/services will be produced.

Figure: The Process Planning and Design Paradigm

Email based Operations Management assignment help - homework help at Expertsmind

Are you searching Operations Management expert for help with Process Planning and Design questions? Process Planning and Design topic is not easier to learn without external help? We at www.expertsmind.com offer finest service of Operations Management assignment help and Operations Management homework help. Live tutors are available for 24x7 hours helping students in their Process Planning and Design related problems. We provide step by step Process Planning and Design question's answers with 100% plagiarism free content. We prepare quality content and notes for Process Planning and Design topic under Operations Management theory and study material. These are avail for subscribed users and they can get advantages anytime.

Why Expertsmind for assignment help

- Higher degree holder and experienced experts network

- Punctuality and responsibility of work

- Quality solution with 100% plagiarism free answers

- Time on Delivery

- Privacy of information and details

- Excellence in solving Operations Management questions in excels and word format.

- Best tutoring assistance 24x7 hours