|

Name of polymer

|

Abbreviat-ion

|

Starting materials (monomers)

|

Nature of polymer

|

Properties

|

Applications

|

|

(i) Polyolefines

|

|

|

|

|

|

|

(a) Polyethylene or polyethene

|

LDPE (Low density polyethene)

|

CH2 = CH2

|

Low density homopolymer (branched) chain growth.

|

Transparent, moderate tensile power, high toughness.

|

Packing material take bags, insulation for electrical wires and cables.

|

|

|

HDPE (high density polyethene)

|

CH2 = CH2

|

High density homopolymer (linear) chain growth.

|

Transluscent, chemically inert, greater tensile strength, toughness.

|

Manufacture of buckets, tubs, house ware, pipes, bottles and toys.

|

|

(b) Polypropylene or polypropene

|

PP

|

CH3 CH = CH2

|

Homopolymer, linear, chain growth.

|

Stronger and Harder than polyethene.

|

Packing of foods, textiles, liners for bags, heat, ropes, automobile mouldings, shrinkage wraps, stronger pipes bottles and carpet fibres.

|

|

(c) Styron or Styrofoam or Polystyrene

|

|

C6H5CH = CH2

|

Homopolymer, linear, chain growth

|

Transparent

|

Plastic toys, house hold wares, radio and television bodies, refrigerator linings.

|

|

(ii) Polyhaloolefines

|

|

CH2 = CH -Cl

Vinyl Chloride

|

|

|

|

|

(a) Polyvinyl chloride

|

PVC

|

|

Homopolymer chains growth

|

Thermoplastic

|

(i) Plasticised with high boiling esters PVC used in rain coats, hand bags, shower curtains, fabrics, shoe soles, vinyl flooring (ii) Good electrical insulator (iii) Hose pipes.

|

|

(b) Teflon or Polytetrafluoroet-hylene

|

PTFE

|

F2C = CF2

|

Homopolymer, high melting point

|

Flexible and inert to solvents boiling acids even aqua regia. Stable upto 598 K.

|

(i) For nonstick utensiles coating (ii) Creating pump packings valves, gaskets, seals, non lubricated bearings.

|

|

(c) Polymonochlorotri-fluroroethylene

|

PCTFE

|

ClFC = CF2

|

Homopolymer

|

Less resistant to heat and chemicals due to presence of chlorine atoms.

|

Similar to those of teflon.

|

|

(iii) Formaldehyde resins

|

|

|

|

|

|

|

(a) Bakelite or Phenol formaldehyde resin

|

|

Phenol and formaldehyde

|

Copolymer, step growth

|

Thermosetting polymer, hard and brittle

|

(i) With low degree polymerisation as bindings glue for wood varnishes, lacquers.

(ii) With greater degree polymerisation for combs, for mica table tops, fountain pen barrels electrical goods (switches and plugs).

|

|

(b) Melamine formaldehyde resin

|

|

Melamine and formaldehyde

|

Copolymer, step growth

|

Thermosetting polymer, hard but not so breakable.

|

Non-breakable crockery.

|

|

(iv) Polyacrylates

|

|

|

|

|

|

|

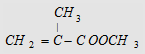

(a) Polymethacrylate (lucite, acrylite and plexiglass and perspex)

|

PMMA

|

|

Copolymer

|

Hard transparent, excellent light transmission, optical clarity better than glass gets up colours.

|

Lenses light covers lights, shades signboards transparent domes skylight, dentures, plastic jewellery and aircraft window.

|

|

(b) Polyethylacrylate

|

|

CH2 = CH - COOC2H5

|

Copolymer

|

Tough, rubber like product

|

|