Master Schedule Formation

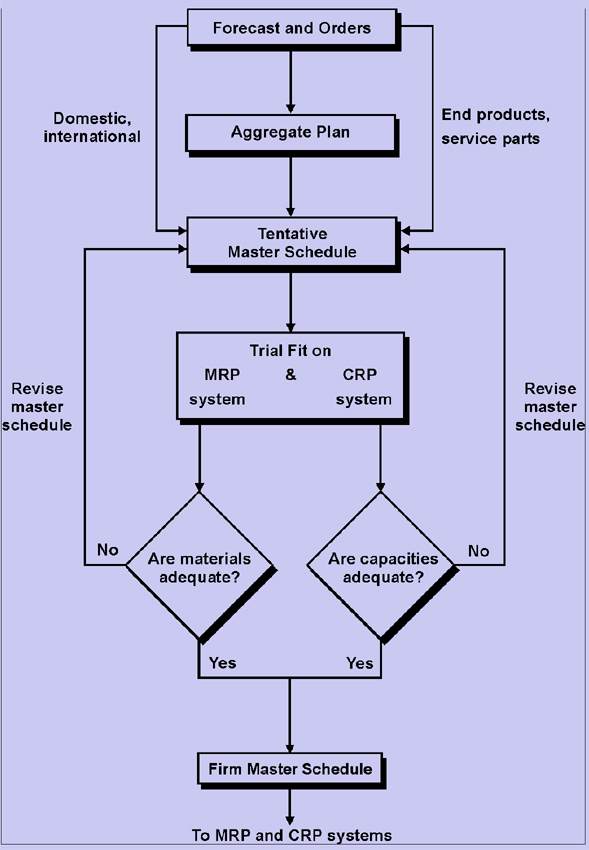

The proper implementation of the master production schedule is important for achieving the goals set in aggregate plans. As the market environment and resource availability influence the aggregate plan, they also affect the master schedule. The influence of the market environment on the master schedule is shown in Figure 9.5.

The two major sources of inputs that influence the MPS are forecasts and customer orders. Make-to-stock environment takes inputs from forecasts in deciding the MPS. On the other hand, make-to-order environment takes inputs from customer demand and based on that generates an MPS.

Make-to-stock items

The major input for the make-to-stock items in master schedule is the demand forecast. Requirements are based on the need to replenish plant or distributor inventories of end products or service parts. MPS for a make-to-stock environment is generated after taking into account the end item level. The products in a make-to-stock environment are produced in batches and the finished goods inventory for all the products are maintained constantly. Examples include FMCG firms and home appliances firms.

Make-to-order items

For make-to-order items, detailed scheduling of time and materials required is essential because the items and quantities specified are unique for a particular customer order. In make-to-order environment, there is no finished goods inventory. Customer orders are backlogged and production begins only after the orders have been placed. An example is jet engine production.

Problem

The forecasted demand for telephone handsets for next six weeks is 30, 35, 38, 32, 32, 30. And the number of orders booked at the start of the MPS planning period is 23, 40, 24, 22, 38, and 22. Prepare an MPS schedule for the telephone set manufacturer.

Given,

Inventory on hand=40

Lead time = 1 week

Production lot size = 80 units

Quantity on hand = 40

Solution

First week Forecast for the first week is 30 units. This requirement can be satisfied by using the on hand inventory.

Projected inventory on hand at the end of first week is = On hand inventory + MPS quantity - projected requirements for the week

= 40 + 0 - 30

= 10

Second week

Forecast for second week is 35 units but the orders received are for 40 units. (when calculating the projected inventory for the week, Inventory on hand at the end of first week is 10 units, which is not sufficient to satisfy the second week's requirements. So to make up for the deficiency, the manufacturer develops a master schedule. As the lead time is one week, the production should commence on first week itself to satisfy the requirements of the second week. As can be seen from the Table 9.3, MPS start quantity for first week is 80 units (production lot size).

Table : MPS for Six Weeks

|

|

1

|

2

|

3

|

4

|

5

|

6

|

|

Forecast

|

30

|

35

|

38

|

32

|

32

|

30

|

|

Orders

|

23

|

40

|

24

|

22

|

38

|

22

|

|

Projected on-hand inventory

|

10

|

50

|

12

|

60

|

22

|

72

|

|

MPS quantity

|

0

|

80

|

0

|

80

|

0

|

80

|

|

MPS start

|

80

|

|

80

|

|

80

|

|

Now at the end of 2nd week projected inventory on hand = On hand inventory + MPS quantity - Projected requirements for the week

= 10 + 80 - 40

= 50 units

Similarly, projected inventory at the end of all six weeks and the MPS quantities can be calculated.

From Table 9.3 we can see there is no requirement of MPS quantities in 1st, 3rd and 5th week.

Email based Operations Management assignment help - homework help at Expertsmind

Are you searching Operations Management expert for help with Master Schedule Formation questions? Master Schedule Formation topic is not easier to learn without external help? We at www.expertsmind.com offer finest service of Operations Management assignment help and Operations Management homework help. Live tutors are available for 24x7 hours helping students in their Master Schedule Formation related problems. We provide step by step Master Schedule Formation question's answers with 100% plagiarism free content. We prepare quality content and notes for Master Schedule Formation topic under Operations Management theory and study material. These are avail for subscribed users and they can get advantages anytime.

Why Expertsmind for assignment help

- Higher degree holder and experienced experts network

- Punctuality and responsibility of work

- Quality solution with 100% plagiarism free answers

- Time on Delivery

- Privacy of information and details

- Excellence in solving Operations Management questions in excels and word format.

- Best tutoring assistance 24x7 hours