Fundamentals of Materials Requirement Planning

Based on the demand for the end product, MRP system disassembles the end product into component parts and subassemblies. MRP is a backward scheduling process that estimates requirement of materials starting with the date of requirement and working backward to estimate date of receipt keeping in view production and waiting time, and estimating date of order, based on delivery lead-time.

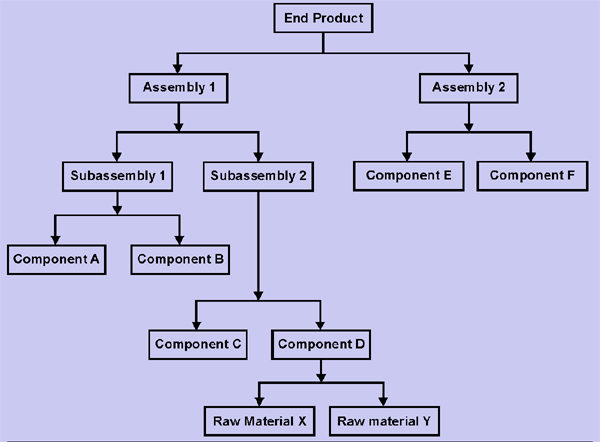

An MRP system helps in coordinating orders from external and internal sources. External orders are referred to as purchase orders and internal orders are referred to as jobs. The system studies the future production requirements and disassembles the end product into required amount of raw materials, parts, subassemblies, and assemblies required in each time bucket (time period) of the planning horizon. It then determines the existing level of inventories for each item and the required order quantities. Figure illustrates how a typical end product is expressed in terms of assemblies, sub-assemblies, components, etc. Finally, a schedule is generated that specifies the time when the items are required. This schedule takes into consideration the time when each item is needed in production, the lead times available for procuring the items, etc. This ensures the availability of parts and materials exactly when they are required in the production process. Ideally, an MRP system aims at replenishing the material stocks when they are required. But, in real world situations, this may not be feasible. As a result, the MRP system regularly examines the production schedule to identify schedule disruptions, and adjusts the material flow to reduce the levels of in-process inventories. Decisions regarding the installation of the MRP system and the features required in the system depend on the type of production and the time considerations in delivering the products to meet the market demand.

MRP is useful for organizations involved in the production of complex products, organizations working with shorter delivery schedules, job-shops and assemble-to-order organizations.

Email based Operations Management assignment help - homework help at Expertsmind

Are you searching Operations Management expert for help with Fundamentals of Materials Requirement Planning questions? Fundamentals of Materials Requirement Planning topic is not easier to learn without external help? We at www.expertsmind.com offer finest service of Operations Management assignment help and Operations Management homework help. Live tutors are available for 24x7 hours helping students in their Fundamentals of Materials Requirement Planning related problems. We provide step by step Fundamentals of Materials Requirement Planning question's answers with 100% plagiarism free content. We prepare quality content and notes for Fundamentals of Materials Requirement Planning topic under Operations Management theory and study material. These are avail for subscribed users and they can get advantages anytime.

Why Expertsmind for assignment help

- Higher degree holder and experienced experts network

- Punctuality and responsibility of work

- Quality solution with 100% plagiarism free answers

- Time on Delivery

- Privacy of information and details

- Excellence in solving Operations Management questions in excels and word format.

- Best tutoring assistance 24x7 hours