According to American branding association, brand is defined as a "name, term, sign, symbol or design, or a combination of them intended to identify the goods and services of one seller or group of sellers and to differentiate them from those of other sellers.’’

We must understand that branding is not only about getting your target market but to chosen over the competition, but it is about getting your prospects to see you as the only one that provides a solution to their problem.

To have a successful brand one must understand the needs and wants of customers and prospects. This can be done by integrating brand strategies through company at every point of public contact. The brand must resides in the hearts and minds of customers, clients, and prospects. It is the sum total of their experiences and perceptions.

The objectives of good brand are:

- Delivering the clear message

- Confirming your credibility

- Connecting to target prospects emotionally

- Motivating the buyer

- Concreting on User Loyalty

How to Define Brand?

• Brand definition to stick evaluation and marketing materials. Question below must be answered to evaluate brand of a company

• What products and/or services are offered? Define the qualities services and/or products of company?

• What are the core values of products and services served?

• What is the mission for company?

• What does the company is specializes in?

• What are target market for company?

• What are the company’s products and services attract?

• What can be tagline of company?

Examine the responses to the questions given above and determine the profile of any brand. Be creative and understand the magic of brand.

Brand lifecycle management, myth or reality related to it?

Building and maintaining distinctive brands was never been more essential. Facing few blockbusters in the pipeline and the onslaught of more savvy and aggressive competitor, companies are more strategically towards developing innovative brands.

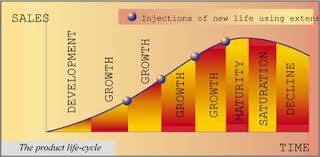

Dealing with the lifecycle of a brand through increasing marketing investment for its launch and satisfying a level of investment may leads to brand go from boom to bust as its patent may turns looms? So how can we can improve return on investment (ROI) through optimizing opportunities at faced at each stage of the brand’s lifecycle

Certainly, Beverage industry is more proficient in brand than ever before; but at the long-term level of applying and leveraging brand, it is missing in translation. The question arises: brand lifecycle management, myth or reality?

Laying the Foundations

Enhancing the opportunity of brand depends on key brand variables like —positioning, personality, brand name and identity. Establishing a clear and planned foundations requires a blueprint of great brands that requires to meet four key criteria:

• Relevance. Understanding the existing brand and its therapy area, the unmet desires arising in the market, the mind-set target audiences, is critical to determine brand opportunity.

• Credibility. The paradigm shift in young customer power may arise compelling push-pull dynamic, which has altered the way of Beverage brand in market. Brand need to speak the youth language.

• Differentiation. It is important that the branding foundations creates differentiation and focus on future brand context, as much as the current brand context.

• Stretch. Finally, these branding foundations should be suitably elastic, to accommodate changes according to the market

Building a brand can never compensate for a poor product; but getting the branding wrong, or failing to unlock the true potential of a brand.

Brand Maintenance

Enhancing opportunity is very important for the lifecycle of the brand accompany with considerable time and investment are used in developing a brand. It is must to consider the to maintain and manage the opportunity for that brand on in launch.

Brand equity, can play a substantial role in helping to maintain a best position and against ultimately erosion of sales and market share by subsequent entrants.

Extending the Brand

Handling the lifecycle of a brand improves "after-life” of product The tools for extending brand is Line extensions, advanced methods of delivery and next generation products launching. The component that will remain constant throughout the lifecycle of a brand: the brand name. As equity in the brand name can be also leveraged. The concept of visual components of the brand, such as use of colour and shape may give a brand positing the market. It may include all forms of intellectual property, patent, trademark and "get-up" should be protected dynamically.

We cannot underestimate equity in the corporate brand. Mostly in the corporate brand of beverage is a glass bottles, cola or orange taste whose added-value, whose benefit proposition that articulated in the hearts and minds of its customers.

Conclusions

Branding characterises a real competitive advantage, but the question remains that is it are making the most of that advantage. A decent product will always be a good product, but when other good entrants to market, the worst of times may began.

We are witnessing rapid change but surely, with companies are focusing on more fundamental level within their organizations. We may see some companies are in still best practices in brand development, in terms of Standard Operating Procedures. Only when we identify the value of upholding, ranging and evolving a brand leading too brand life cycle management a reality.

The best example of branding Coca- cola

In this case study we have answers for these questions by delineation of the manufacturing processes for Coca-Cola - international brand from London to Lagos, Los Angeles to Lahore. It is sold in more and more markets, generating thousands of jobs in the local economies. Coco-Cola runs its business in franchisee bases where bottling and canning operations are conducted.

Resource handling at coco cola

• Coca-Cola's bottlers and canners are processed and transformed into the bottles and cans of drink.

• The transforming of resources are done the managers, employees, machinery and equipment.

• While the transformed resources are the materials (the cans, bottles, liquids, etc.) converted into finished product.

Manufacturing process at Coco-cola

Mostly, Coca-Cola is manufactured by franchisees of the world’s leading bottling and canning companies. These franchisees are controlled by The Coca-Cola Company.

Soft drinks manufacturing is a very competitive business as lot may leading brands are putting effort to be number one company. The Manufacturing techniques of these companies are continually improving due to new technologies. This leads to premier quality standards aiming its products to be cost effective. For illustration, a very small change in the shape of the Can may leads to save a millions of dollars in production costs.

The production of Coca-Cola involves two major tasks:

• Its packaging material

• Its bottling and canning and the finished drink.

Packaging at coco cola In last few decades , Coca-Cola was produced in glass bottles but it cost high as well as leads to distribution of bulky bottles was very inconvenient that’s why manufactured had close glass bottling system . In new era new packaging methods have revolutionised the process. Now the Advanced bottling and canning technology transformed Coca-Cola cans and bottles into very light and extremely strong. The Company has devoted a lot of time and money for research and development to increase the life cycle of its brand. Now the Cans and plastic bottles are simply crushed and recycled at the end.

Preparing of fill cans Can are distributed in huge volume to a canning plant. Where the cans are moulded like an open cup at last the ring pull end is fitted. After inspection it is checked that there are no faults, each can goes through a soaking machine to make sure it is clean and are for ready for filling.

Preparing the drink

Coca-Cola contains concentrated beverage base and liquid sweetener which is pooled with syrup then drink is made. The Company ships gathers the bottling and can where the franchisees mix it with sugar and local water. Then the water is passed from a filters to make sure it is completely pure.

Carbon dioxide, which turns it into fizzy. Then it is stored and then piped into the manufacturing process passing through carbonator and cooler. The Company lay down parameter that on what equipment franchisees will use for these processes.

Samples are taken on frequent basis for chemical analysis, and staff everyday checks and ensure that plants are retaining the Company's standards of sanitation and excellence. The Company offers its franchisees with the latest technology and statistical process control methods.

Filling the cans: The packaging of finished drinks are pooled with a rapid filling process. Each minute hundreds of cans passes through a robotic manufacturing line and are filled with a particular amount of Coca-Cola. When the cans move along with the production line, they are ringed pull end and produce the finished can. In the end it is are inspected that they are smooth and do not have any gaps or leaks.

An individual code is stamped on the cans so that each one can be traced back to the point and time of production. A date code is applied to ensure product freshness. The cans now appear like those you will see in the shops.

Promising the class of the product : The production of Coca-Cola is carried by processes which is called continuous flow production. On a production line, it is a process that tends to continually repeat and like products go through the same order .Constant flow production takes place by using computer-controlled automatic equipment to produce coco-cola. The Company uses Total Quality Management procedures that inspire everyone in the plant to produce quality work. All employees tries to satisfy customers and places them at the soul of the production process. By frequently seeking improvement at every aspect of production so that employees can eliminate problems. Within the production process, quality control is monitored and take few test samples of product. To guarantee that there are no errors in the product, quality control inspectors take statistically select some samples at the completion of the production line.

By chemical analysis, these inspectors can ensure that the products are meeting the specifications; they also check that there are no errors in the packaging of product. A 'fill height detector’ is used to check that the cans are filled to the right quantity. Those Cans which are not suitably filled are rejected.

Packing of end product into cases The canners are then distributed to retailers such as supermarkets, shops and garages with the help of a case former, machine which creates the casing that protects the cans .These cans are now stored provisionally in a warehouse before they are collected by large distribution trucks.

Bottling of Coca-Cola In the bottling process PET (plastic) is used, which is very similar to glass .Franchisees accept cans that previously have the logo and any promotional details on bottles. At the end, bottles are automatically wrapped with a cap immediately after they have been filled.

Just-in-time Canners and bottlers are in immense quantities of materials each week. The receiving of the raw materials and delivering the finished products take’s a complex sequence of actions. The best solution is when the inputs arrive for 'just-in-time' so they gets converted into a finished product get ready for transportation purpose 'just-in-time' help retailers to meet need.

These packagers involve in sophisticated supply chain networks with the supermarket chains and other outlets to ensure that this process are running smoothly. Canners and bottlers must ensure that there are no bulky stockpiles of cans waiting to be sold. It leads to progressive information technology which rapidly relays figures for demand for Coca-Cola. For example, demand tends rises in periods of warmer weather so the packagers have to increased production.

Conclusion The world's best known product, The Coca-Cola Company has to serve the peak quality processes and launch standards that guarantee the production of a standardised product which meets consumers' expectations all the time.

In order to get highest standards the Company has had to cultivate a close bond with its franchisees. Total Quality Management, is heart of this process involving a continuous emphasis on getting quality standards right every time and on constantly seeking new ways to improve recital.