Hand Driven Rivets:

In these rivets, driving is completed manually by hammers.

Power driven rivets are preferred to hand driven ones and are allowed higher stresses. Also rivets may be either shop rivets or field rivets depending upon the conditions under which they are driven. Shop rivets are driven in workshops under controlled conditions and expert supervision and hence allowed 10% higher stresses than field's rivets which are driven by semi-skilled field workers at work sites.

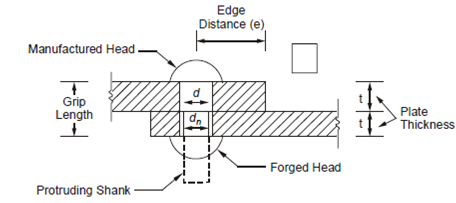

A rivet holes are made slightly larger than the diameter of the shank of the undriven rivets.

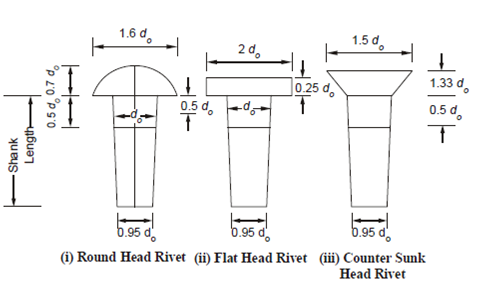

The rivets heads are made of different shapes and they are sometimes named after the shape of their heads, example for Round head, Flat-head, or Counter-sunk head rivets (Figure (a)).

(a) Various Types of Rivets

(b) Riveted Connection of Plates

Figure

More knowledge information regarding rivets are available in IS 1929: 1982 (Rivets for General Purposes (12-48 mm diameter)) and IS 2155: 1962 (Rivets for General Purpose (below 12 mm diameter)).