Pearlite

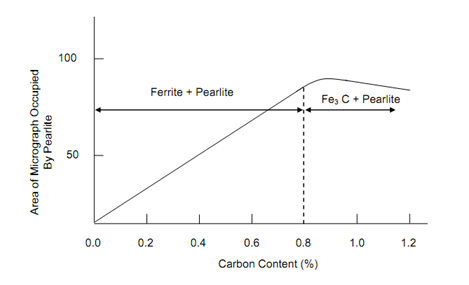

The tensile strength of pure iron (0.00% C) is around 250 N/mm2 which increases to about 850 N/mm2 at a carbon percentage of 0.8. At extremely low carbon percentage the entire metal is made up of ferrite grains which are soft and ductile. With increasing carbon percentage more and more material is made up of pearlite, a substance that seem to have colour of mother-of-pearl, hence the name. At 0.4% carbon pearlite occupies almost half the area viewed through microscope. At this level of carbon the tensile strength is approx 540 N/mm2. At 0.8% carbon almost total area consists of pearlite with a strength of 850 N/mm2.

Examination of pearlite at higher magnification (X 1500) reveals that it has a laminated structure. It is a composite consisting of alternate layers of ferrite and cementite.Cementite provides the strength while ferrite retains ductility of steel. At carbon content above 0.8% the quantity of Fe3C begins to increase and steel begins to lose its ductility. Figure illustrated relationship between pearlite and carbon content. Outside the region of Figure , within the range of carbon between 0.9 and 1.2% pearlite structure still exists but grains are surrounded by cementite network. These cementite networks not being parts of grains are referred to as free cementite and are the cause of brittleness in steel. In general the strength of steel does not enhance because of the presence of free cementite, later on it might decrease below the level of 0.8% carbon steel.

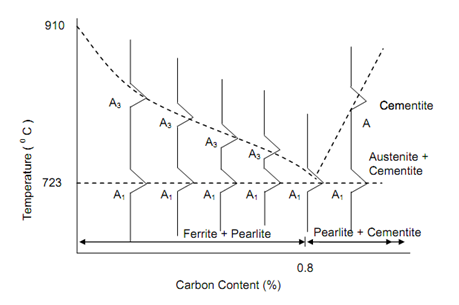

Since pearlite is an important constituent of steel is control becomes important if properties of steel are to be controlled. It shall be worthwhile to understand how it is formed. With reference to Figure 7 three forms of iron were recognized. These forms are referred to as allotropic forms of iron and at each of transformation a thermal arrest is experienced.

Figure: Relationship between Pearlite % and Carbon Content

Throughout the cooling of pure iron the transformation from γ-iron (fcc) to α-iron (bcc) occurs at a unique temperature of 910oC. Though, carbon is added to the iron to form steel this transformation takes place over a range of temperatures. The limits of this range are known as the critical points and the higher temperature at which transformation starts during cooling is designated A3. The lower point is designated like as A1. It was stated in previous Section that the lower temperature A1 remains constant at 723oC irrespective of the carbon content while the higher temperature A3 gradually reduces as carbon percentage increases at a carbon percentage of 0.8, A3 and A1 are equal to 723oC. If carbon percentage further increases, A3 also enhanced. The equilibrium diagram will be obtained if A3 and A1 temperatures are plotted against carbon percentage as seen in Figure .The detailed phase diagram has already been presented in Figure. This diagram shows how γ-iron which is austenite is transformed into pearlite.

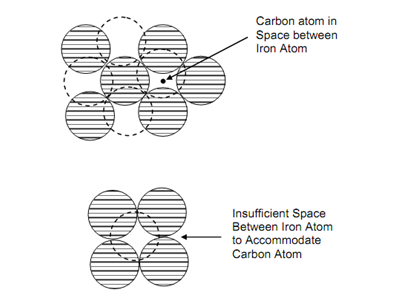

It may be noted that carbon solubility is different in austenite than in ferrite. The fcc (γ-iron) can hold as much as 1.7% carbon in solution at 1130oC. Within the range of carbon under discussion the structure is entirely austenite at this temperature and all the carbon is in solution. The carbon is interstitially dissolved or in other words, a carbon atom does not replace an iron atom to form part of the cube. When the lattice is arranged to have a bcc structure the carbon atoms is ejected from its site because space is insufficient. It is the reaction that takes place at A3.

Figure: Critical Points for Carbon Steel

Figure: Interstitial Solution of Carbon

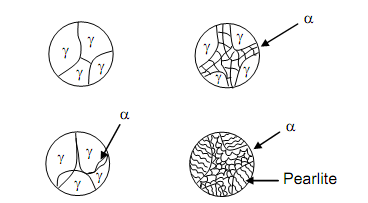

The sequence of events between temperatures A2 and A1 is illustrated in Figure 16 throughout which austenite transforms into pearlite. The bcc ferrite grains nucleate at boundaries of austenite grains. As the temperature decrease the ferrite covers more and more are in austenite grain which reduces in size. The separation of ferrite through austenite will result in rejection of carbon which shall be absorbed by remaining austenite. Thus the remaining austenite gets richer in carbon until the amount of carbon reaches 0.8% causing precipitation of layers of cementite in the austenite region. Thus, the austenite transforms into pearlite consisting of layers of cementite and ferrite. Thus transformation of austenite is similar to eutectic reaction but since it occurs in the solid state it is termed eutectoid transformation. This eutectoid reaction takes place at temperature of 723oC which is termed A1. For this cause pearlite is also frequently referred as eutectoid.

Figure: Transformation of Austenite in 0.4% C Steel, as Cooling occurs from Molten State above A3 Temperature