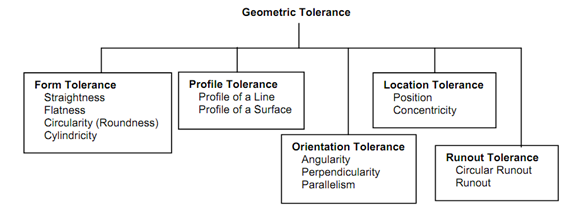

Types of Geometric Tolerances

Geometric tolerancing specifies the tolerance of geometric characteristics. There are following three types of geometric tolerances.

- Size tolerance

- Location tolerance

- Form tolerance

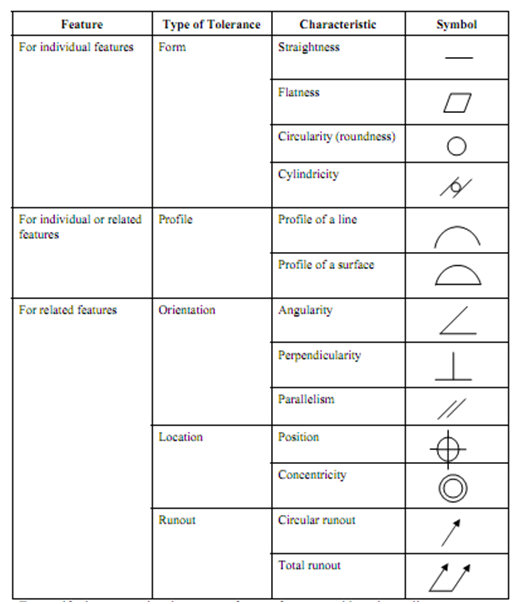

Basic geometric characteristics as defined by the ANSI Y14.5 M 1982 standard include:

Symbols that represent these features are illustrated in Table 1 below.

Table 1 : ANSI Symbols for Geometric Tolerancing

In order to specify the geometric tolerances, reference features - lines, planes or surfaces might be established. A datum is a surface, plane points(s), line, axis, or other source of information concerning an object. Datums are supposed to be exact, and from them dimensions same to the reference-location dimensions in the conventional drawing system can be established. Though, datum's are utilized only for geometric dimensioning.

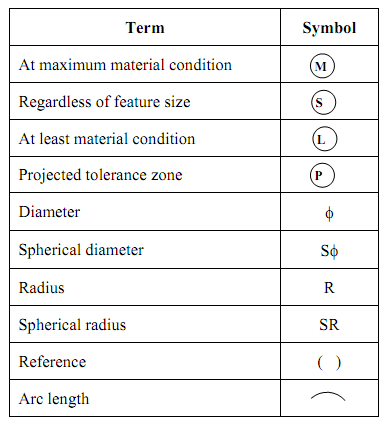

Symbolic modifiers are utilized to clarify implied tolerances. The maximum material condition (MMC) might be used to constrain the tolerance of the generated dimension and the maximum designed dimension. It might be defined as the condition of a part feature where the maximum amount of material is contained. For instance, maximum size of a shaft or minimum size of a hole. Least material condition (LMC) specifies the opposite of the maximum material condition. They might be applied only while both of the following conditions hold :

a. Two or more features are interrelated w. r. t. the location or form (that means two holes). At least one of the features might refer to size.

b. MMC or LMC must directly reference a size feature.

c. ANSI modifying symbols are illustrated in Table 2.

Table 2 : ANSI Modifying Symbols

When LMC or MMC are utilized to specify the tolerance of a shaft or hole, it implies that the tolerance specified is constrained by the maximum or least material condition as well as some other dimensional feature(s). The tolerance might increase when the actual produced feature size is larger (for a hole) or smaller (for a shaft) than the MMC size. Because enhance in the tolerance is compensated by the deviance of size in production, the last combined hole-size error and geometric tolerance error shall still be larger than the anticipated smallest hole.

The third modifier is "Regardless of feature size" (RFS). This is the default modifier when LMC or MMC is not specifically mentioned. While RFS is used, the geometric tolerance specified is independent of the size of part.